Imagine a world where industrial processes run smoothly—no leaks, no pressure mishaps. Too often, manufacturers face frustrating failures tied to traditional pressure sensing technology. Enter the sputtered thin film pressure transmitter, a solution that’s transforming how we measure and manage pressure within various systems. Why do failures always occur during crucial production moments? Often, it’s due to outdated methods that fall short.

Flaws in Traditional Solutions

Traditional pressure transmitters, while useful, are plagued by issues like drift and temperature dependence. They often struggle to provide accurate readings under varying conditions. These limitations can lead to catastrophic failures, resulting in costly downtime. In critical applications, a mere blip in accuracy can translate to significant risk and expenses. Look, it’s simpler than you think; these outdated systems just can’t keep up in today’s demanding environments.

New Technology Principles

The sputtered thin film technology is changing the game. By employing a thin film of conductive material, these transmitters achieve unparalleled precision and stability. They are less sensitive to environmental changes, providing consistent readings that help keep operations running smoothly. Innovative designs also enhance durability—after all, who wants to deal with constant replacements?

Quantified User Benefits

Users of sputtered thin film pressure transmitters often report a stark reduction in maintenance costs and downtime. With accuracy improving by nearly 30% in certain applications, the investment pays itself back quickly. Enhanced reliability also fosters confidence among engineers, leading to smoother operational workflows. Plus, these transmitters boast impressive biocompatibility for medical applications, showing just how versatile this technology can be.

Always Evaluate These Metrics

When choosing the right pressure transmitter for your needs, remember to always verify these three metrics: ① Accuracy—how precise is it under specific conditions? ② Environmental resilience—can it withstand your operating conditions? ③ Cost-efficiency—what does the total lifecycle cost look like? By asking these questions, you’ll ensure you invest in a solution that truly meets your requirements.

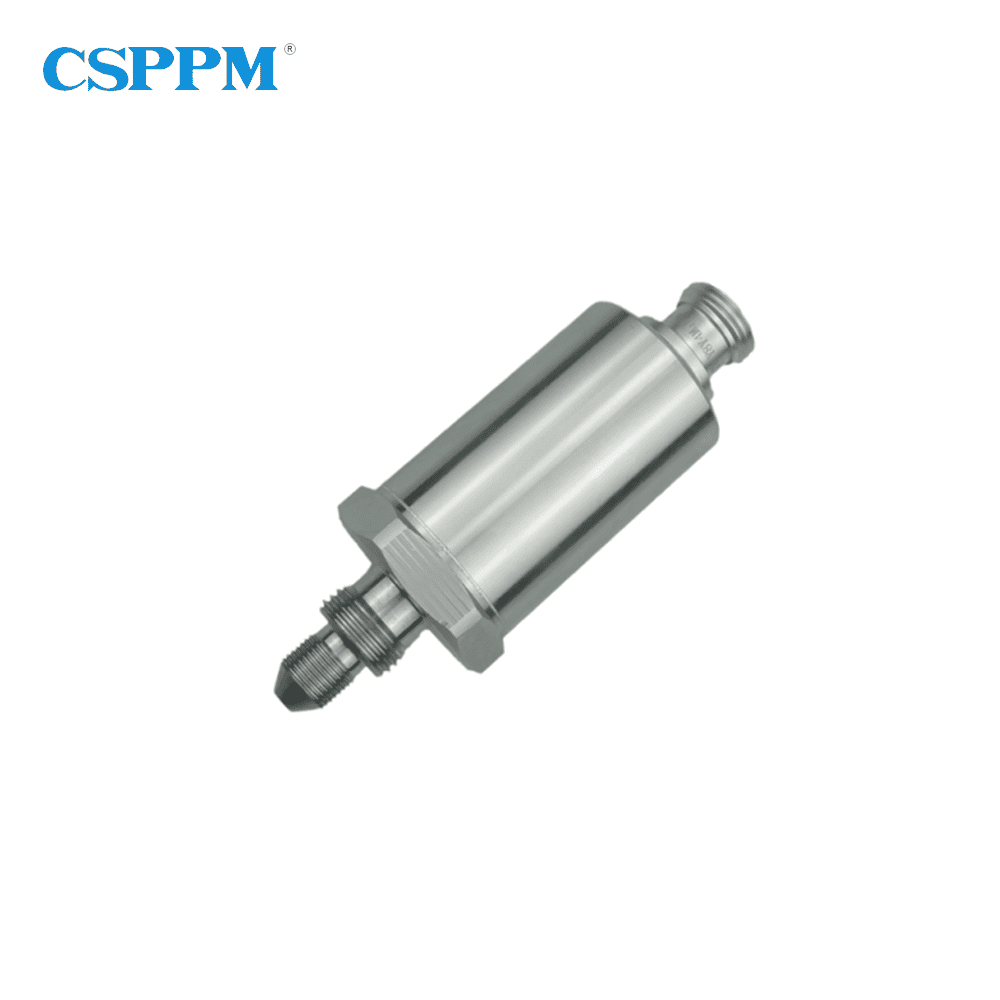

Delving into Stainless Steel Pressure Transmitters

In industries where sanitation and durability are paramount, the stainless steel pressure transmitter plays a crucial role. They resist corrosion while providing reliable pressure data, fundamentally important in food and pharmaceutical sectors. Stainless steel’s inherent strength empowers these devices to maintain accuracy even in harsh environments, making them a favored choice among manufacturers. With their easy-to-clean surfaces, they not only fulfill technical specifications but also adhere to strict regulatory requirements without a hitch. Manufacturers who overlook this material risk reliability—remember, it’s all about choosing robust systems that stand the test of time.

Exploring Industrial Pressure Transmitters

Industrial processes are complex beasts requiring precise control mechanisms. This is where the industrial pressure transmitter comes into play, seamlessly streamlining operations. With advancements in technology, these transmitter types can handle higher pressures and more extreme conditions, proving indispensable in sectors like oil and gas. They manage workflows efficiently by delivering accurate data, minimizing risks associated with pressure fluctuations that could lead to disasters. Plus, the modern designs incorporate features like wireless monitoring, opening the door for better data collection and process optimization. Facilities that adopt these devices usually witness improved overall performance and greater safety, underscoring the piece’s importance in modern industrial setups.

Conclusion: Choose CSSPM Sensor for Your Pressure Solutions

In summary, understanding the nuances of pressure transmitters—especially sputtered thin film technology—can significantly enhance your operational efficiency. The core of success doesn’t just rely on the technology itself but also on choosing a trustworthy manufacturer who understands your needs. When it comes to dependable pressure measurement solutions, look no further than CSSPM Sensor. With supply advantages and a commitment to quality, they stand as a preferred resource in the industry. Always ensure you evaluate the critical metrics outlined earlier, so you secure the most effective and reliable solutions for your applications. Don’t settle for anything less than precision!