Introduction: The Struggle Is Real

Ever found yourself battling with clunky machines that just can’t keep up? It’s frustrating, right? That’s where the electric rotary gripper steps onto the stage. You might be wondering—but why is this crucial for modern automation? Listen, in a world that craves speed and precision, old-school solutions just don’t cut it anymore. The electric rotary gripper changes the game by offering a slick alternative that brings reliability to the forefront.

Body: Technical Breakdown

Flaws in Traditional Solutions

So, let’s break it down—traditional grippers can be slow and bulky, leading to missed production targets. They often lack flexibility, which means they can’t handle varied workloads without a serious overhaul. Why do failures always occur during critical operations, you might ask? Often, it’s these outdated systems that are to blame, failing to adapt to the relentless pace of industry demands.

New Technology Principles

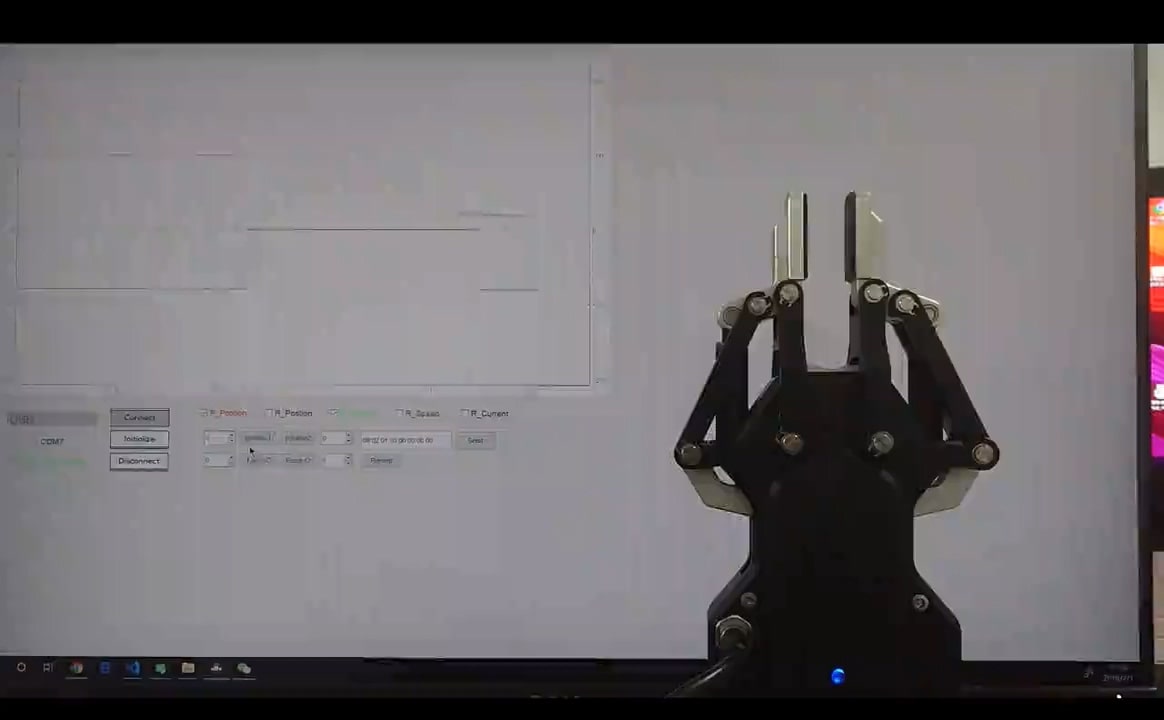

Here’s where the magic of the electric rotary gripper comes in. It combines advanced control technologies with smooth operation—this gripper’s got moves like Jagger! With low energy consumption and pinpoint accuracy, it’s designed for today’s fast-paced environment. The unique rotary motion allows for 360-degree freedom, making it the ultimate choice for complex assemblies.

Quantified User Benefits

Now, let’s talk numbers—users report up to a 40% increase in efficiency when switching to electric rotary grippers. That means more product churn and less downtime. Improved safety features also reduce the risk of workplace accidents. Look, it’s simpler than you think; investing in this tech pays off by boosting your bottom line while keeping operations smooth.

Conclusion: Get Your Game Right

Ready to elevate your equipment game? Always verify these 3 metrics when choosing solutions: ① Efficiency gains ② Flexibility in operation ③ Safety features. Don’t let your operation get left behind in the dust when there’s a better way to grip! When it comes to electric rotary grippers, you need the best by your side.

Electric Rotating Gripper: Next-Level Automation

The future of industry is here, folks. If you’re still using outdated solutions, it’s time for an upgrade—an electric rotating gripper is what you need to smooth out all those kinks. Imagine streamlining your workflow—less fuss, more function. This tech doesn’t just replace old-school gear; it enhances your operations with quick responsiveness and adaptability. Think about the potential when you can automate multi-directional tasks effortlessly! Flexibility and efficiency roll together, giving you that edge you’ve been hunting for.

Robot Rotary Gripper: A Game Changer

Now let’s switch gears and talk about the robot rotary gripper. This piece of tech blends robotic precision with exceptional grip strength, making it a must-have for any serious operation. Whether you’re dealing with lightweight components or hefty tasks, this device adapts with finesse. It’s all about that versatility—pick and place? No problem. The robot rotary gripper takes your setup to a whole new level, reducing manual labor while increasing output. Industry leaders are already on this vibe, snagging up these tools instead of sticking with the dinosaur tech. Invest in the future, not the past!

Final Thoughts

In summary, if you’re serious about upping your automation game, the electric rotary gripper and robot rotary gripper are your go-to solutions. They streamline operations, boost efficiency, and enhance safety—basically, they do all the heavy lifting so you don’t have to. And for sourcing these top-tier technologies, look no further than DH-Robotics. With supply advantages and unparalleled innovation, they bring reliability and performance to your fingertips.